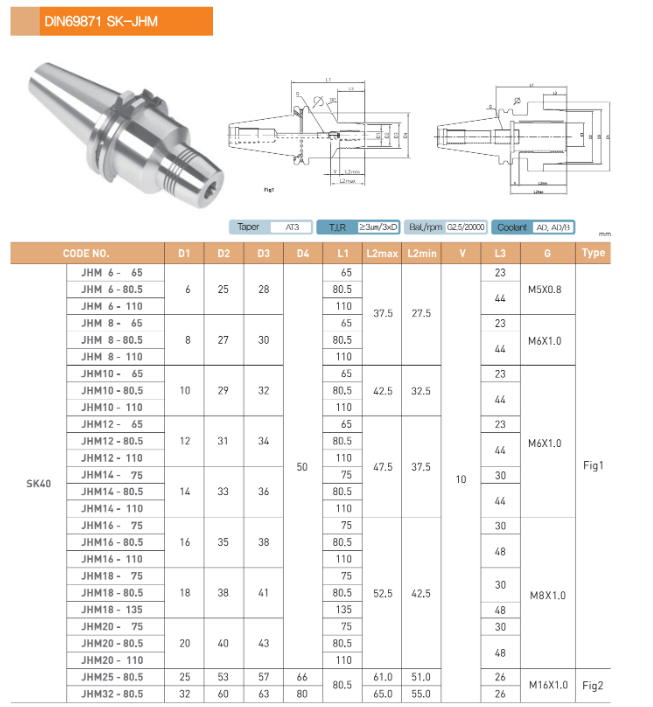

SK40-JHM HYDRAULIC CHUCK – JE-IL SOLUTION

SK40-JHM Hydraulic Chuck have special clamping method by removing and expansion the sleeve which were brazed on inside of chuck. This method completely clamping a cutting tool on all around inner bore face of chuck and keep high precision and proper for high speed maching as well.

Advantages of SK40-JHM Hydraulic chuck:

- Fine finishing, High speed & high accuracy machining, Reaming, Drilling, etc.

- Below 3µm at 3 x D / This high accuracy extend tool life including improving machining condition.

- Easy Clamping and Un clamping by T-Wrench. It is able to tool change after assembing the chuck into the spindle of Machine.

- Center through coolant system (AD) + Flange through coolant system (B).

- Even under high speed, it works very fast without vibration and makes sure of fine process and safety with fine balance up to G2.5/25,000rpm (Max.) = G6.3/60,000rpm.

Note of caution when operating SK40-JHM Hydraulic chuck:

- Please fully clamping the clamping screw by T-Wrench (the clamping screw will be stopped, if it was fully clamped by human power)

- Please fully insert a cutting tool into the chuck. At the least, tool shank edge to be arrived at 8mm from end of the inner bore depth.

- Please eliminate a dust or tiny chip or humidity in the tool shank and inner bore face of the chuck.

- Please do not pull out the Clamping Screw and Oil Sealing from the chuck.

- Please do not using hydraulic chuck for rough cutting.

- Please do not disposal it by oneself when come out operating problem such as broken the chuck or clamping & unclamping problem etc.

If you have some problem for the hydraulic chuck, please contact us at first.

Đánh giá

Chưa có đánh giá nào.

Sản phẩm tương tự

ĐẦU KẸP THỦY LỰC - HYDRAULIC CHUCK

ĐẦU KẸP THỦY LỰC - HYDRAULIC CHUCK

ĐẦU KẸP THỦY LỰC - HYDRAULIC CHUCK

ĐẦU KẸP THỦY LỰC - HYDRAULIC CHUCK

ĐẦU KẸP THỦY LỰC - HYDRAULIC CHUCK

ĐẦU KẸP THỦY LỰC - HYDRAULIC CHUCK

ĐẦU KẸP THỦY LỰC - HYDRAULIC CHUCK

ĐẦU KẸP THỦY LỰC - HYDRAULIC CHUCK

Hãy là người đầu tiên nhận xét “SK40-JHM”